Baking molds come in many different materials and coatings. Materials are divided into three categories: porcelain, metal, and plastic. Coatings include non-stick coatings and regular layers. Non-stick coatings are enamel and spray coating, while regular layers are anodized and hard coatings. This article mainly explains non-stick spray, which is subdivided into water-based spray and oil-based spray. Water-based spraying is fluoro resin (Teflon, polytetrafluoroethylene), and oil-based spraying is silicone resin (solvent-based).

The difference between fluoro resin and silicone resin is that fluoro resin has shortcomings such as high curing temperature, complex construction process, low gloss of the coating film, and single color, which limits its application scope. Therefore, the curing temperature of silicone resin is very low. It has the advantages of relatively low gloss, high gloss, variable colors, and easy coating, so it is widely used.

Some consumers asked, is silicone paint toxic? The answer is: non-toxic. No toxins will be produced at normal use temperature (260°C). The general baking temperature is below 220℃. In the field of food safety, all silicone resin coatings used are food grade and have undergone strict safety testing. Moreover, the silicone resin is solvent-based and has excellent thermal oxidation stability, high-temperature insulation performance, outstanding weather resistance, waterproofness, salt spray resistance, and mildew resistance.

An overall summary of the advantages of using silicone resin:

1. Low surface energy and good antifouling performance;

2. No toxin;

3. Good wettability to the substrate;

4. The curing conditions are relatively mild;

5. High hardness, hot hardness, solvent resistance, wear resistance, flexibility and weather resistance;

6. Economical and environmentally friendly.

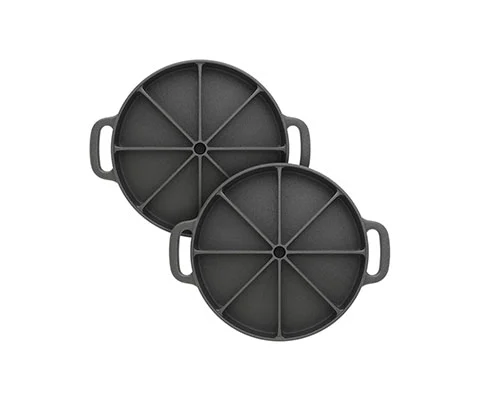

Therefore, the silicone resin is usually used in household appliances such as beverage utensils, kitchenware, baking utensils, rice cooker inner pots, bread buckets, frying pans, barbecue plates, non stick pan pancakes, toasters, induction cooker panels, electric iron boards, etc. - high-temperature resistance - Sticky coating. The EMP customized baking mold series are all silicone coated to ensure that the products bring a healthy and safe experience to consumers. If interested, please contact us to learn more about custom kitchenware products!

English

English 中文

中文 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch italiano

italiano Suomi

Suomi dansk

dansk Svenska

Svenska